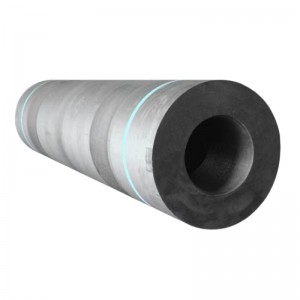

UHP 500mm Dia 20 Inch Furnace Graphite Electrode With Nipples

Technical Parameter

Physical & Chemical Properties For D500mm(20”) Electrode & Nipple

|

Parameter |

Part |

Unit |

UHP 500mm(20”) Data |

|

Nominal Diameter |

Electrode |

mm(inch) |

500 |

|

Max Diameter |

mm |

511 |

|

|

Min Diameter |

mm |

505 |

|

|

Nominal Length |

mm |

1800/2400 |

|

|

Max Length |

mm |

1900/2500 |

|

|

Min Length |

mm |

1700/2300 |

|

|

Max Current Density |

KA/cm2 |

18-27 |

|

|

Current Carrying Capacity |

A |

38000-55000 |

|

|

Specific Resistance |

Electrode |

μΩm |

4.5-5.6 |

|

Nipple |

3.4-3.8 |

||

|

Flexural Strength |

Electrode |

Mpa |

≥12.0 |

|

Nipple |

≥22.0 |

||

|

Young’s Modulus |

Electrode |

Gpa |

≤13.0 |

|

Nipple |

≤18.0 |

||

|

Bulk Density |

Electrode |

g/cm3 |

1.68-1.72 |

|

Nipple |

1.78-1.84 |

||

|

C.T.E. |

Electrode |

×10-6/℃ |

≤1.2 |

|

Nipple |

≤1.0 |

||

|

Ash Content |

Electrode |

% |

≤0.2 |

|

Nipple |

≤0.2 |

NOTE:Any specific requirement on dimension can be offered.

Applications

- Electric Arc Furnace

Graphite electrode are main used in the modern steelmaking process, Electric Arc Furnace is widely recognized as one of the most efficient and reliable tools. An electric arc furnace uses graphite electrodes to create high temperatures and generate current, which is then used to melt recycled steel scrap. As the diameter of the graphite electrode plays a vital role in creating the necessary level of heat and ensuring a high-quality end product, using the right electrode is crucial for achieving optimal results. According to the capacity of the electric furnace,different diameter graphite electrodes are equipped in order to make the graphite electrodes continue to be used,the graphite electrode are connected by nipples. - Submerged Electric Furnace

The Submerged Electric Furnace is a revolutionary product that is designed to meet the needs of modern industry. This state-of-the-art furnace features a UHP graphite electrode that is specially crafted to improve the efficiency of the melting process. The graphite electrode in the Submerged Electric Furnace is mainly used to produce ferroalloys, pure silicon, yellow phosphorus, matte and calcium carbide. The unique design of this electric furnace sets it apart from traditional furnaces, as it allows for a part of the conductive electrode to be buried in the charging materials. - Resistance Furnace

Resistance furnaces are used to produce high-quality graphite products such as UHP graphite electrodes. These electrodes are widely used in the electric arc furnace steelmaking process to produce high-performance steel. The UHP graphite electrode is known for its high thermal conductivity, low electrical resistance, and resistance to thermal shock. These properties make them an ideal choice for the steelmaking process. UHP graphite electrodes are produced by a high-temperature graphitization process inside a resistance furnace.

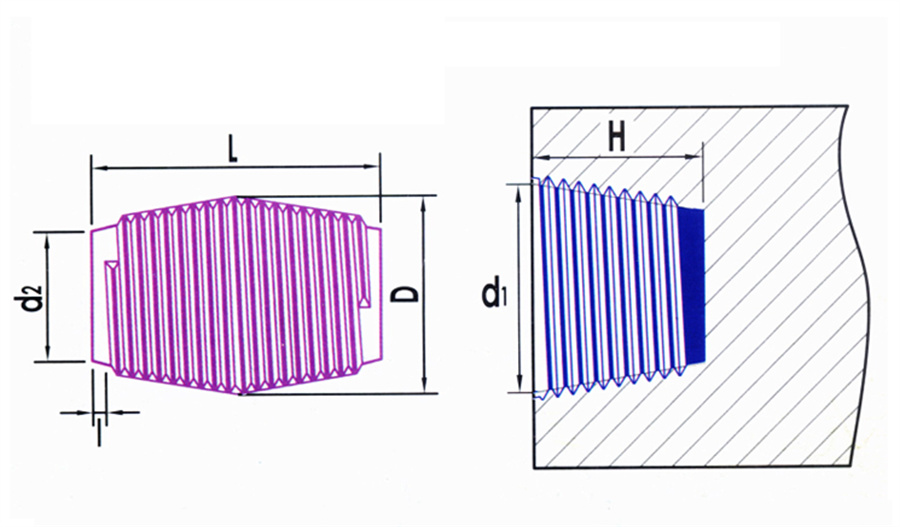

Gufan Cabon Conical Nipple and Socket Drawing

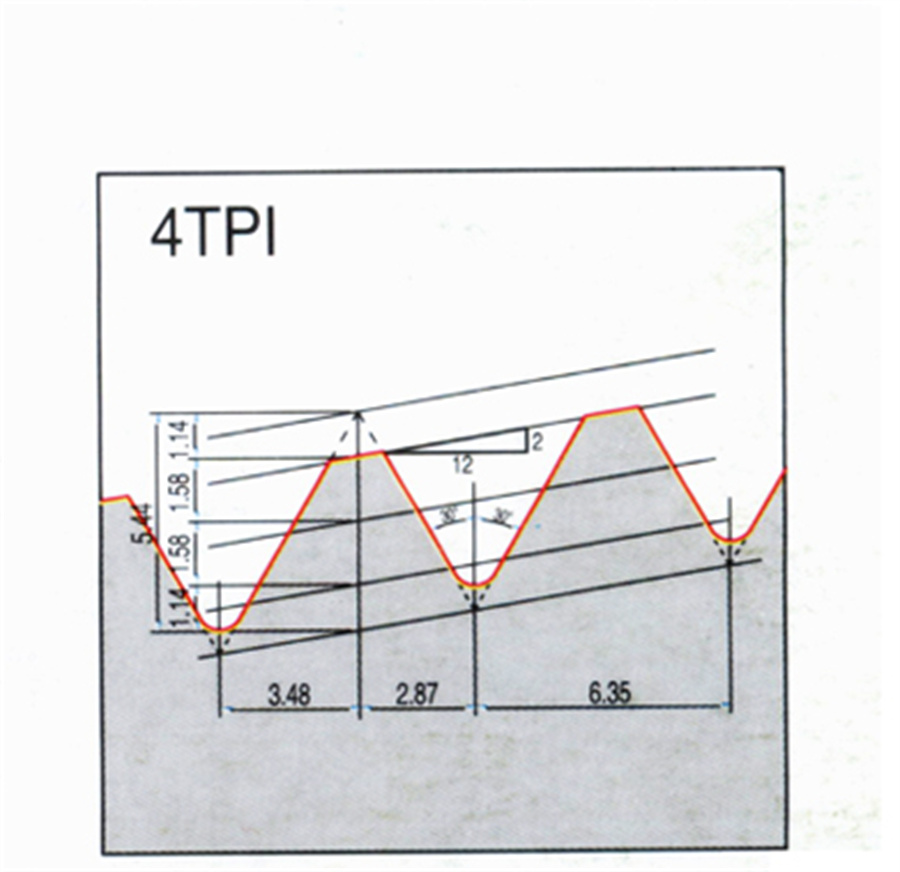

Gufan Carbon Conical Nipple and Socket Dimensions(4TPI)

|

Gufan Carbon Conical Nipple and Socket Dimensions(4TPI) |

|||||||||

|

Nominal Diameter |

IEC Code |

Sizes of Nipple (mm) |

Sizes of Socket(mm) |

Thread |

|||||

|

mm |

inch |

D |

L |

d2 |

I |

d1 |

H |

mm |

|

|

Tolerance (-0.5~0) |

Tolerance (-1~0) |

Tolerance (-5~0) |

Tolerance (0~0.5) |

Tolerance (0~7) |

|||||

|

200 |

8 |

122T4N |

122.24 |

177.80 |

80.00 |

<7 |

115.92 |

94.90 |

6.35 |

|

250 |

10 |

152T4N |

152.40 |

190.50 |

108.00 |

146.08 |

101.30 |

||

|

300 |

12 |

177T4N |

177.80 |

215.90 |

129.20 |

171.48 |

114.00 |

||

|

350 |

14 |

203T4N |

203.20 |

254.00 |

148.20 |

196.88 |

133.00 |

||

|

400 |

16 |

222T4N |

222.25 |

304.80 |

158.80 |

215.93 |

158.40 |

||

|

400 |

16 |

222T4L |

222.25 |

355.60 |

150.00 |

215.93 |

183.80 |

||

|

450 |

18 |

241T4N |

241.30 |

304.80 |

177.90 |

234.98 |

158.40 |

||

|

450 |

18 |

241T4L |

241.30 |

355.60 |

169.42 |

234.98 |

183.80 |

||

|

500 |

20 |

269T4N |

269.88 |

355.60 |

198.00 |

263.56 |

183.80 |

||

|

500 |

20 |

269T4L |

269.88 |

457.20 |

181.08 |

263.56 |

234.60 |

||

|

550 |

22 |

298T4N |

298.45 |

355.60 |

226.58 |

292.13 |

183.80 |

||

|

550 |

22 |

298T4L |

298.45 |

457.20 |

209.65 |

292.13 |

234.60 |

||

|

600 |

24 |

317T4N |

317.50 |

355.60 |

245.63 |

311.18 |

183.80 |

||

|

600 |

24 |

317T4L |

317.50 |

457.20 |

228.70 |

311.18 |

234.60 |

||