Small Diameter Furnace Graphite Electrode for electric arc furnace for steel and foundry industry

Technical Parameter

Chart 1:Technical Parameter For Small Diameter Graphite Electrode

|

Diameter |

Part |

Resistance |

Flexural Strength |

Young Modulus |

Density |

C.T.E |

Ash |

|

|

Inch |

mm |

μΩ·m |

MPa |

GPa |

g/cm3 |

×10-6/℃ |

% |

|

|

3 |

75 |

Electrode |

7.5-8.5 |

≥9.0 |

≤9.3 |

1.55-1.64 |

≤2.4 |

≤0.3 |

|

Nipple |

5.8-6.5 |

≥16.0 |

≤13.0 |

≥1.74 |

≤2.0 |

≤0.3 |

||

|

4 |

100 |

Electrode |

7.5-8.5 |

≥9.0 |

≤9.3 |

1.55-1.64 |

≤2.4 |

≤0.3 |

|

Nipple |

5.8-6.5 |

≥16.0 |

≤13.0 |

≥1.74 |

≤2.0 |

≤0.3 |

||

|

6 |

150 |

Electrode |

7.5-8.5 |

≥8.5 |

≤9.3 |

1.55-1.63 |

≤2.4 |

≤0.3 |

|

Nipple |

5.8-6.5 |

≥16.0 |

≤13.0 |

≥1.74 |

≤2.0 |

≤0.3 |

||

|

8 |

200 |

Electrode |

7.5-8.5 |

≥8.5 |

≤9.3 |

1.55-1.63 |

≤2.4 |

≤0.3 |

|

Nipple |

5.8-6.5 |

≥16.0 |

≤13.0 |

≥1.74 |

≤2.0 |

≤0.3 |

||

|

9 |

225 |

Electrode |

7.5-8.5 |

≥8.5 |

≤9.3 |

1.55-1.63 |

≤2.4 |

≤0.3 |

|

Nipple |

5.8-6.5 |

≥16.0 |

≤13.0 |

≥1.74 |

≤2.0 |

≤0.3 |

||

|

10 |

250 |

Electrode |

7.5-8.5 |

≥8.5 |

≤9.3 |

1.55-1.63 |

≤2.4 |

≤0.3 |

|

Nipple |

5.8-6.5 |

≥16.0 |

≤13.0 |

≥1.74 |

≤2.0 |

≤0.3 |

||

Chart 2:Current Carrying Capacity For Small Diameter Graphite Electrode

|

Diameter |

Current Load |

Current Density |

Diameter |

Current Load |

Current Density |

||

|

Inch |

mm |

A |

A/m2 |

Inch |

mm |

A |

A/m2 |

|

3 |

75 |

1000-1400 |

22-31 |

6 |

150 |

3000-4500 |

16-25 |

|

4 |

100 |

1500-2400 |

19-30 |

8 |

200 |

5000-6900 |

15-21 |

|

5 |

130 |

2200-3400 |

17-26 |

10 |

250 |

7000-10000 |

14-20 |

Chart 3: Graphite Electrode Size & Tolerance For Small Diameter Graphite Electrode

|

Nominal Diameter |

Actual Diameter(mm) |

Nominal Length |

Tolerance |

|||

|

Inch |

mm |

Max. |

Min. |

mm |

Inch |

mm |

|

3 |

75 |

77 |

74 |

1000 |

40 |

-75~+50 |

|

4 |

100 |

102 |

99 |

1200 |

48 |

-75~+50 |

|

6 |

150 |

154 |

151 |

1600 |

60 |

±100 |

|

8 |

200 |

204 |

201 |

1600 |

60 |

±100 |

|

9 |

225 |

230 |

226 |

1600/1800 |

60/72 |

±100 |

|

10 |

250 |

256 |

252 |

1600/1800 |

60/72 |

±100 |

Main Application

- Calcium carbide smelting

- Carborundum production

- Corundum refining

- Rare metals smelting

- Ferrosilicon plant refractory

Instruction Handing And Using For Graphite Electrodes

1.Remove the protective cover of the new electrode hole, check whether the thread in the electrode hole is complete and the thread is incomplete, contact the professional engineers to determine whether the electrode can be used;

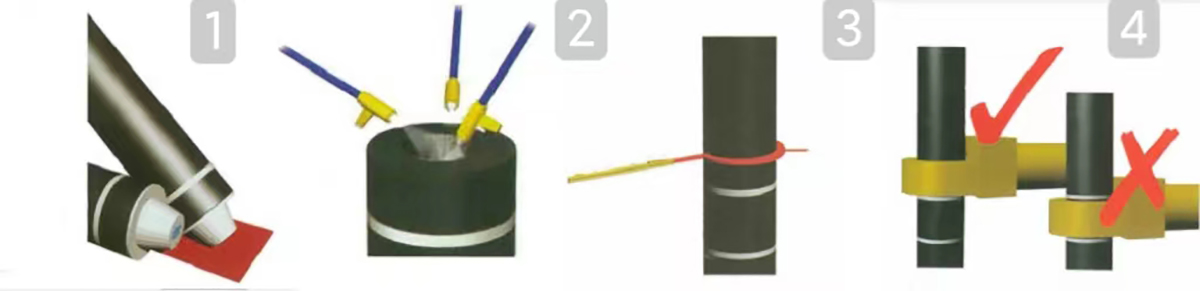

2.Screw the electrode hanger into the electrode hole at one end, and place the soft cushion under the other end of the electrode to avoid damaging the electrode joint;(see pic1)

3.Use compressed air to blow the dust and sundries on the surface and hole of the connecting electrode, and then clean the surface and connector of the new electrode, clean it with a brush;(see pic2)

4.Lift the new electrode above the pending electrode to align with the electrode hole and fall slowly;

5.Use a proper torque value to properly lock electrode;(see pic3)

6.Clamp holder should be placed out of the alarm line.(see pic4)

7.In the refining period, it is easy to make the electrode thin and cause breaking, joint fall off, increase electrode consumption, please don’t use electrodes to raise carbon content.

8.Due to the different raw materials used by each manufacturer and the manufacturing process, the physical and chemical properties of electrodes and joints of each manufacturer. So in use, under general circumstances, Please don’t mixed use electrodes and joints produced by different manufacturers.