Silicon Graphite Crucible For Metal Melting Clay Crucibles Casting Steel

Technical Parameter For Clay Graphite Crucible

|

SIC |

C |

Modulus of Rupture |

Temperature Resistance |

Bulk Density |

Apparent Porosity |

|

≥ 40% |

≥ 35% |

≥10Mpa |

1790℃ |

≥2.2 G/CM3 |

≤15% |

|

Note:We can adjust the content of each raw material to produce the crucible according customers’ requirement. |

|||||

Description

The graphite used in these crucibles is usually made from petroleum coke,The clay used is typically a mixture of kaolin clay and ball clay, which is blended together in specific proportions to form a fine powder. This powder is then mixed with water to form a paste, which is poured into molds.

Clay graphite crucibles find their use in a broad range of industries. The most common application of these crucibles is in the foundry industry, where they are used for melting and casting metals such as iron, brass, aluminum, and bronze. They are also used in the jewelry industry for melting precious metals such as gold and silver. Other industries where clay graphite crucibles are used include the semiconductor industry, where they are used to melt and cast silicon, and the glass industry, where they are used for melting and pouring molten glass.

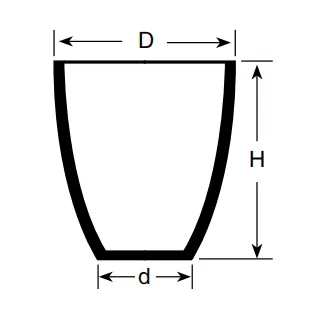

Clay Graphite Crucible Size Chart

|

No. |

Height (mm) |

Upper OD (mm) |

Bottom OD (mm) |

No. |

Height (mm) |

Upper OD (mm) |

Bottom OD (mm) |

|

2# |

100 |

90 |

50 |

100# |

380 |

325 |

225 |

|

10# |

173 |

162 |

95 |

120# |

400 |

347 |

230 |

|

10# |

175 |

150 |

110 |

150# |

435 |

355 |

255 |

|

12# |

180 |

155 |

105 |

200# |

440 |

420 |

270 |

|

20# |

240 |

190 |

130 |

250# |

510 |

420 |

300 |

|

30# |

260 |

210 |

145 |

300# |

520 |

435 |

310 |

|

30# |

300 |

237 |

170 |

400# |

690 |

510 |

320 |

|

40# |

325 |

275 |

185 |

500# |

740 |

540 |

330 |

|

70# |

350 |

280 |

190 |

500# |

700 |

470 |

450 |

|

80# |

360 |

300 |

195 |

800# |

800 |

700 |

500 |

Instructions And Cautions For Graphite Crucible

Graphite crucible is an exceptional product for industrial applications. Follow these vital instructions and precautions to ensure the longevity and efficient performance of the graphite crucible.

- Avoid any mechanical impact to graphite crucible.

- Avoid dropping or hitting the crucible from a high place.

- Keep graphite crucible away moisture place.

- Graphite crucibles are not waterproof,after drying,not touch the water.

- Use a round mouth patch or fine sandpaper to clean up any residues.

- Use a round mouth patch or fine sandpaper to clean up any residues.

- Using the crucible for the first time,take it slow and gradually increase the heat over time.