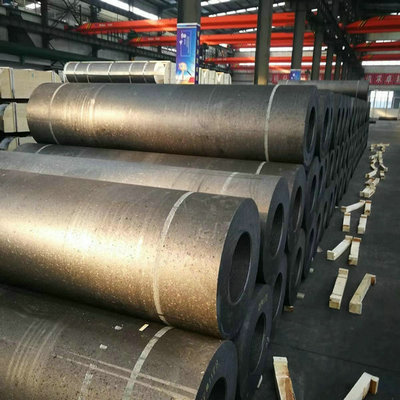

Graphite electrodes are essential components in electric arc furnaces used for steel production. The demand for graphite electrodes has been on the rise in recent years, driven by the growth of the steel industry and the increasing use of electric arc furnaces. As a result, the graphite electrode market has experienced significant fluctuations in prices, impacting steel manufacturers and other industries reliant on these critical components.

Understanding the factors that influence graphite electrode prices is crucial for steel producers and other stakeholders in the industry.

Factors Affecting Graphite Electrode Prices

1. Raw Material Costs: The primary raw material used in the production of graphite electrodes is petroleum coke. Fluctuations in the prices of petroleum coke directly impact the overall production costs of graphite electrodes, subsequently influencing their market prices. Additionally, the availability and quality of needle coke, a key raw material in the production of high-quality graphite electrodes, also play a significant role in determining prices.

2. Supply and Demand Dynamics: The demand for graphite electrodes is closely tied to the steel industry’s performance, as electric arc furnaces are widely used in steel production. When steel production is high, the demand for graphite electrodes increases, leading to higher prices. Conversely, during periods of reduced steel production, the demand for graphite electrodes decreases, resulting in lower prices.

3. Production Capacity and Utilization: The global graphite electrode market is characterized by a limited number of manufacturers, and the production capacity of graphite electrodes is relatively constrained. Any disruptions in production, such as plant closures or maintenance shutdowns, can lead to supply shortages and subsequently drive up prices. Conversely, when production capacity is underutilized, it can lead to oversupply and downward pressure on prices.

4. Environmental Regulations: The production of graphite electrodes involves energy-intensive processes that can have environmental implications. Stringent environmental regulations and policies can impact production costs, leading to potential price adjustments in the market. Compliance with environmental standards may require additional investments in pollution control equipment, which can contribute to higher production costs and, consequently, higher prices for graphite electrodes.

5. Currency Exchange Rates: Graphite electrode prices are also influenced by currency exchange rates, especially for global manufacturers and buyers. Fluctuations in exchange rates can impact the cost of imported raw materials and the competitiveness of graphite electrode exports, ultimately affecting market prices.

Graphite electrode prices are influenced by a complex interplay of factors, including raw material costs, supply-demand dynamics, production capacity, environmental regulations, and trade considerations. The market has experienced significant price volatility in recent years, posing challenges and opportunities for industry participants. Looking ahead, the future outlook for graphite electrode prices will be shaped by the growth of the steel industry, technological advancements, environmental considerations, and geopolitical factors. Understanding these dynamics and staying abreast of market trends will be essential for stakeholders to make informed decisions and navigate the evolving landscape of the graphite electrode market.

Post time: Mar-26-2024