Graphite Electrodes In Electrolysis HP 450mm 18inch For Arc Furnace Graphite Electrode

Technical Parameter

|

Parameter |

Part |

Unit |

HP 450mm(18”) Data |

|

Nominal Diameter |

Electrode |

mm(inch) |

450 |

|

Max Diameter |

mm |

460 |

|

|

Min Diameter |

mm |

454 |

|

|

Nominal Length |

mm |

1800/2400 |

|

|

Max Length |

mm |

1900/2500 |

|

|

Min Length |

mm |

1700/2300 |

|

|

Current Density |

KA/cm2 |

15-24 |

|

|

Current Carrying Capacity |

A |

25000-40000 |

|

|

Specific Resistance |

Electrode |

μΩm |

5.2-6.5 |

|

Nipple |

3.5-4.5 |

||

|

Flexural Strength |

Electrode |

Mpa |

≥11.0 |

|

Nipple |

≥20.0 |

||

|

Young’s Modulus |

Electrode |

Gpa |

≤12.0 |

|

Nipple |

≤15.0 |

||

|

Bulk Density |

Electrode |

g/cm3 |

1.68-1.72 |

|

Nipple |

1.78-1.84 |

||

|

C.T.E. |

Electrode |

×10-6/℃ |

≤2.0 |

|

Nipple |

≤1.8 |

||

|

Ash Content |

Electrode |

% |

≤0.2 |

|

Nipple |

≤0.2 |

NOTE:Any specific requirement on dimension can be offered.

Product Characteristics

- Anti-oxidation treatment for longevity.

- Low electric resistance.

- High-purity,high-density,strong chemical stability.

- Good thermal conductivity and electrical conductivity

- High machining accuracy,good surface finishing.

- High mechanical strength,low electrical resistance.

- Resistant to cracking & spallation.

- High resistance to oxidation and thermal shock.

- Low ash,Its ash content is controlled within 3%.

- Dense and equal structure,Low graphite electrode consumption.

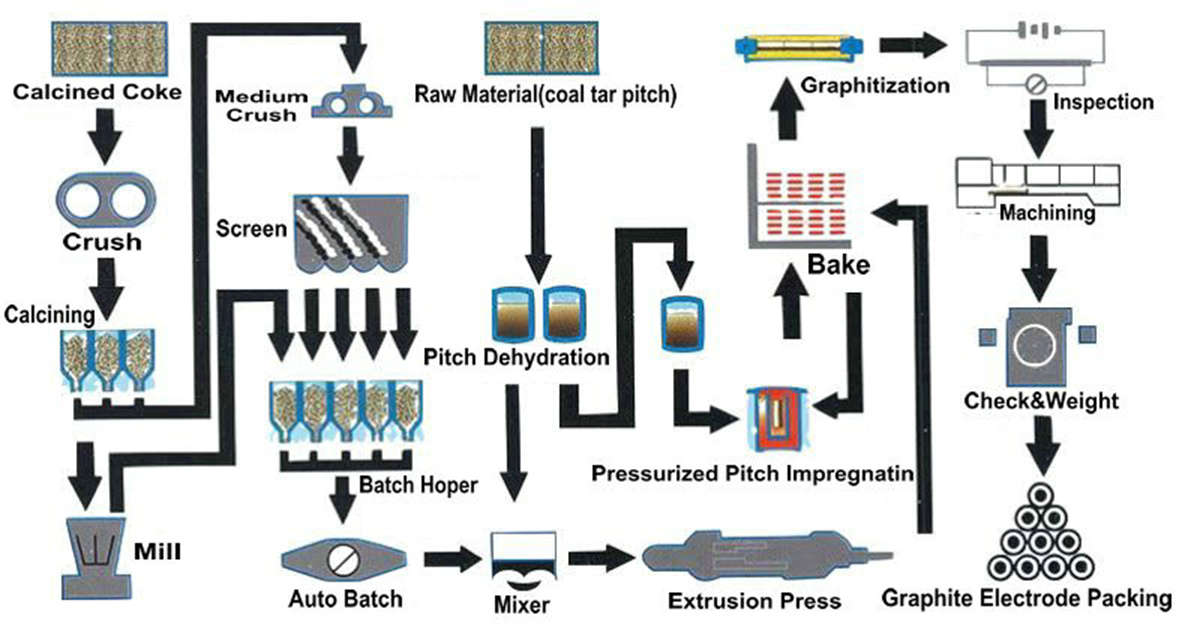

Production Process

The process of manufacturing high power(HP) grade graphite electrode involves several steps. First, the raw materials are carefully selected, ensuring that they are of the highest quality. Petroleum coke, needle coke, and coal asphalt are then mixed together in a predetermined ratio. The mixture is then processed to form a green block, which is then treated with an impregnation process. This process involves the use of a special type of pitch, which is designed to penetrate the green block and strengthen it.After impregnation, the green block is then baked in a controlled environment to create a solid electrode.

HP Graphite Electrode Current Carrying Capacity Chart

| Nominal Diameter |

High Power(HP) Grade Graphite Electrode |

||

|

mm |

Inch |

Current Carrying Capacity(A) |

Current Density(A/cm2) |

|

300 |

12 |

13000-17500 |

17-24 |

|

350 |

14 |

17400-24000 |

17-24 |

|

400 |

16 |

21000-31000 |

16-24 |

|

450 |

18 |

25000-40000 |

15-24 |

|

500 |

20 |

30000-48000 |

15-24 |

|

550 |

22 |

34000-53000 |

14-22 |

|

600 |

24 |

38000-58000 |

13-21 |