High Power Graphite Electrode For EAF LF Smelting Steel HP350 14inch

Technical Parameter

|

Parameter |

Part |

Unit |

HP 350mm(14”) Data |

|

Nominal Diameter |

Electrode |

mm(inch) |

350(14) |

|

Max Diameter |

mm |

358 |

|

|

Min Diameter |

mm |

352 |

|

|

Nominal Length |

mm |

1600/1800 |

|

|

Max Length |

mm |

1700/1900 |

|

|

Min Length |

mm |

1500/1700 |

|

|

Current Density |

KA/cm2 |

17-24 |

|

|

Current Carrying Capacity |

A |

17400-24000 |

|

|

Specific Resistance |

Electrode |

μΩm |

5.2-6.5 |

|

Nipple |

3.5-4.5 |

||

|

Flexural Strength |

Electrode |

Mpa |

≥11.0 |

|

Nipple |

≥20.0 |

||

|

Young’s Modulus |

Electrode |

Gpa |

≤12.0 |

|

Nipple |

≤15.0 |

||

|

Bulk Density |

Electrode |

g/cm3 |

1.68-1.72 |

|

Nipple |

1.78-1.84 |

||

|

C.T.E. |

Electrode |

×10-6/℃ |

≤2.0 |

|

Nipple |

≤1.8 |

||

|

Ash Content |

Electrode |

% |

≤0.2 |

|

Nipple |

≤0.2 |

NOTE:Any specific requirement on dimension can be offered.

Instruction For Nipple Installation

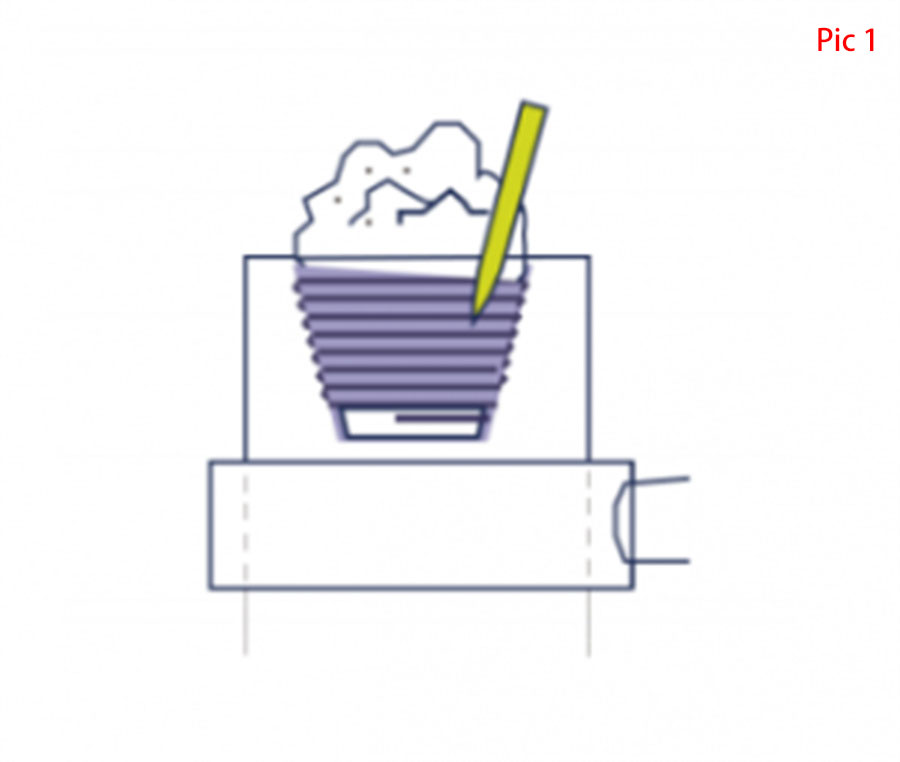

1.Before installing the graphite electrode nipple, Clean dust and dirt on the surface and socket of electrode and nipple with compressed air; (see pic1)

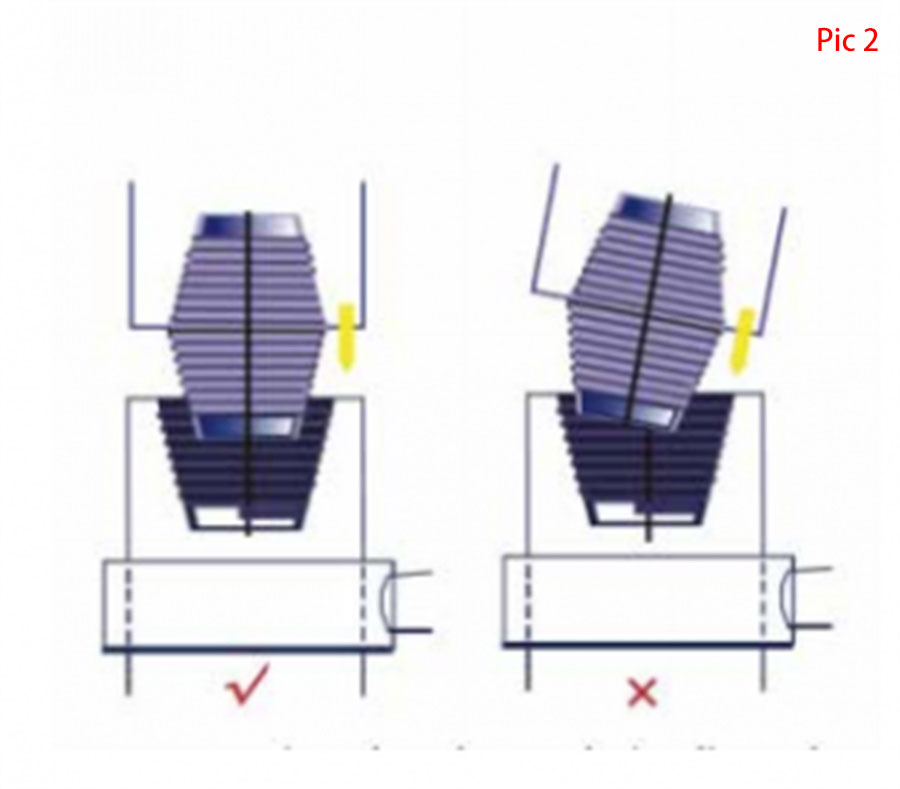

2.The middle line of graphite electrode nipple should be kept consistent during two pieces graphite electrodes joint together; (see pic2)

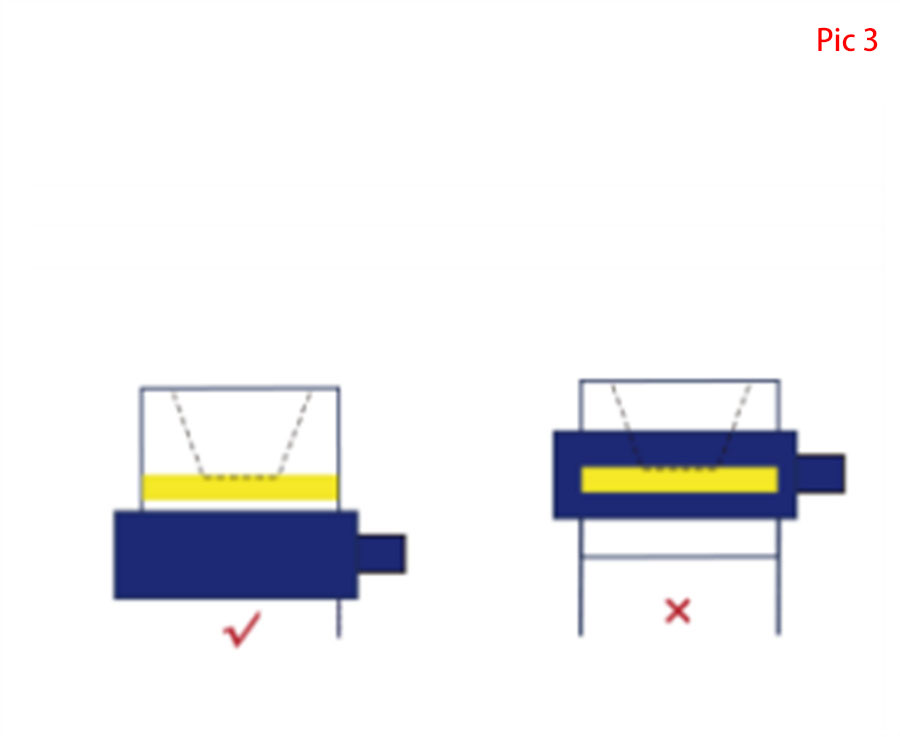

3.Electrode clamper must be hold at the proper position: outside the safety lines of the higher end; (see pic3)

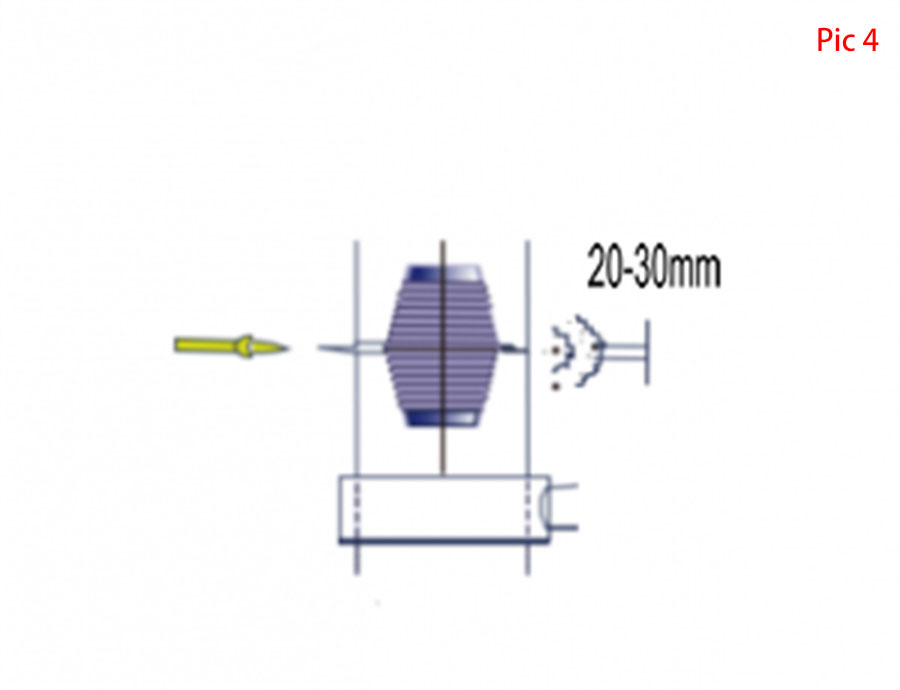

4.Before tightening the nipple,ensure the nipple surface clean without dust or dirty. (see pic4)

Recommended Guideline For Transport And Storing

1.Operate carefully to prevent slipping due to the tilt of the electrode and breaking the electrode;

2.In order to ensure the electrode end surface and electrode thread, please do not hook the electrode at both ends of the electrode with an iron hook;

3.It should be taken lightly to prevent hitting the joint and causing thread damage When loading and unloading;

4.Don’t pile the electrodes and joints directly on the ground, Should put on the wooden or iron frame to prevent the electrode damage or stick to the soil, Do not remove the packaging before use in order to to prevent dust, debris falling on the thread or electrode hole;

5.Electrodes should be placed neatly in the warehouse, and both sides of the stack should be padded to prevent sliding. The stacking height of the electrodes is generally not more than 2 meters;

6.Storage electrodes should pay attention to rain and moisture-proof. Wet electrodes should be dried before use to avoid crack and increase of oxidation during steel making;

7.Store the electrode connector not close to the high temperature to prevent the high temperature from melting the joint bolt.